Thuringian Water Hones

There are a number of these currently available, of different grits. The German company Mueller (MST) mines them and grits available are 6000, 8000 and 10,000, although the last one is most commonly encountered. They are used with a rubbing stone to create a milky slurry and can provide excellent results, although sometimes they have small, hard crystalline deposits in them. Much is made about these deposits in razor forums, but they can be plucked out with the tip of a knife and the small depression left will do no harm. The edges are quite commonly chamfered off at an oblique angle too – this is not seen as a flaw – it is done in-factory to remove any sharp brittle or broken edges. These hones are quite versatile and may be used with a heavy slurry to cut quite quickly. Using a heavy slurry gives the Thuringian a cutting speed of a stone of slightly lower grit rating, but it will leave a slightly rounded edge. Working out the slurry by increasingly diluting it with plain water until just water is left will give the best edge – very sharp, but smooth at the same time, something like a coticule (but I must point out that my personal preference is for the Thuringian).

The most famous water hone from this region was the Escher water hone – there were a number of varieties, classified by colour, and grits were in the region of 11,000 – 12,000. The area has long since been mined-out, but Mueller did find some stock of old stone that had not been cut and began offering them as NOS (New Old Stock) Thuringian hones (note that Escher was really the trademark of a certain company). Sometimes these were available as small narrow hones in boxes, labelled “The Celebrated Thuringian Water Hone” and similar, with a label in the lid of the box – a small cup symbol with E&S in it stands for Escher & Sohne (not all have this mark – the E&S ones were specially selected). I have had one of these, a small stone, and it did give an extremely good edge. These stones do not need to be soaked before use. The real vintage Escher Thuringian Water Hones are sublime to use, especially in the larger sizes. They leave an incredible edge and a lot of users prefer them over the natural Japanese stones (see below).

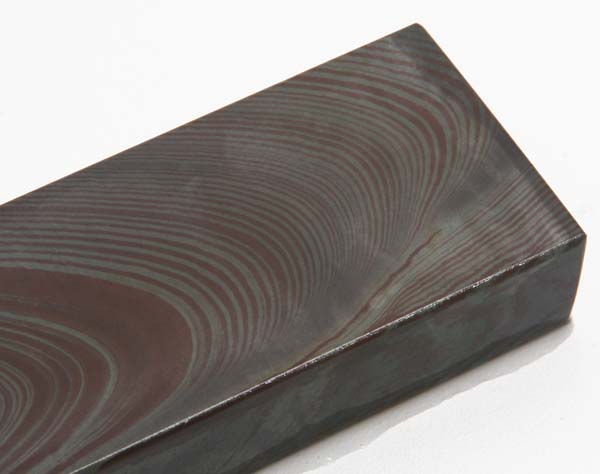

Above: a NOS Thuringian. Note that “Echter” is german for ‘real’ or ‘genuine’ – not to be confused with “Escher” which was a name and trademark.

Welsh Honing Slate

Although these are slates, they are mica-rich and it is this to which they owe their honing characteristics. The hone is still mined today in a variety of types. One such is the Dragons Tongue comes with a milled surface from the mine, which is no good for razors – it needs to be lapped. If done properly the surface can become quite “velvety” – you have to see it to understand what I mean. It is a fairly slow stone but increases in speed if used with a slurry. I would rate it at about 8,000 on average – some specimens may be higher, others lower. It does not need to be soaked before use. Other types of welsh honing slate are black, green or purple. Lately, some outrageously high grit equivalent figures have been given to these stones. If buying, bear in mind that somewhere around 10k, possible 11k, is the best they are capable of.

Chinese 12000

A cheap stone and a great finishing stone from the Guangxi province of China. It is very hard, almost glass-like in use with little feedback. A lot of people use it as a finishing hone followed by a strop pasted with chrome oxide, but in my opinion, if you do enough laps on the stone you don’t need the pasted strop. It is very, very slow – frequently needing 100 laps to do its job, but these can be cut in half if used with a slurry. A 1000/6000 King, an MST Thuringian and one of these make for a versatile and very cost-effective package. For some absurd reason it is often recommended that the Chinese 12000 is soaked before use – it even appears on one of the various types of packaging they come in. They are so hard and adamantine that I think you would have to soak one for months to get any water penetration – my advice is to save yourself the bother and just pour a puddle of water on it. The hardness makes them a bit of a chore to lap, too. I’m not convinced that they are really 12000 grit either – I have used a fair number, some performed a little worse than the Welsh Honing Slate, others about the same.

Arkansas Stones

There are a number of types of Arkansas stones available. They come from North America and are composed of virtually pure novaculite, a very hard, dense substance. The grades are soft, hard, surgical black and translucent. Don’t go by colour – the colour comes from trace minerals and the same colours may be found in different types of Arkansas stone. Only two types need concern the open razor user – the surgical black and the translucent. Confusingly, although there is already a category recognised as “hard” these two are termed “true hard.” The surgical type – so-called because it was much in demand for sharpening surgical implements – comes in black or blue-black colours while the translucent comes in many attractive shades: white, grey, pink, etc. Another confusing thing is that they cannot be classified by grit rating – rather, they are classified by specific gravity. The finest stones (surgical and translucent) would only rate a lowly 1200+ if rated by grit, but they polish like a very high-grit stone.

The only one I would bother with is the translucent – this is a superb finisher and gives an extremely fine edge. It is very slow in use and is used without slurry or a rubbing stone. It is so hard that it can ruin a diamond plate if you try to lap it with one! The great Italian razor maker Mastro Livi uses one as the final stone in one of his videos – if it is good enough for him then it’s probably good enough for anyone!

Above: a translucent white Arkansas stone. Note that it looks a bit chalky in the picture, but in real life, it has a translucent milky quality and if you put a strong light source behind it the translucency, particularly at the edges, is clear.

Charnley Forest Hone

A very hard stone from Charnwood Forest in Leicestershire (the old parish was called Charnley, hence the name, but in antiquity, they were also called Charlie hones). They give a particularly fine edge. In Sheffield at the height of the razor-making area they were often used to “strike-off” the wire edge from a razor that had been freshly ground because of their hardness, but I challenge anybody to find an old reference to them being used to actually hone razors back then – the mythical ‘cutlers green stone’ and a few others were reserved for this purpose). They may be used with light oil or water. Using oil will give a slightly more refined edge. Many of these vintage stones come in custom made hardwood boxes, which are saturated with oil, and the stone is often quite heavily dished. It is a bit of a pain to lap – anything more than a slight dishing may take several hours to redress. There are basically two types of Charnley hone:

The above is the green/red-figured variety, often with beautiful markings and swirls. These have to be examined quite closely, as most of the defects associated with this hone appear in the darker markings and include “pinny” inclusions which may damage the razor’s edge unless they are picked out. They range in finishing ability – old manuals say that this type is slightly inferior and coarser than the plain type, but the best examples of both are quite evenly matched.

Above is the plainer, darker variety – not so mossy green as the figured variety but usually an excellent finishing hone – the old manuals rate this type as best. Both types may be used with a small rubbing stone of the same material to speed-up the polishing process, which is quite slow. Finish with plain water, though, for the best edge.

Welsh Oil Stone

These are also known as Lynn Idwal hones. Sometimes mistaken for a plain Charnley (purposely so by unscrupulous sellers on auction websites!), these are cheaper than Charnley Forest Hones, more plentiful, harder (usually – some softer variants exist) and give a slightly less refined edge than the CF. They leave an edge on a razor that gives a crisp, clean shave. An edge from a CF will give as close or closer a shave but will be a bit smoother. Most tend to be a muted green/grey colour, and they have an obvious glassy nature. Impacts in the past to the surface leave a visible percussion fracture and the hone itself is prone to a number of conchoidal (i.e. shell-like) fractures and splitting.

There are other variants of this hone. One is spotted and looks remarkably like a sort of Tam O’Shanter and surprisingly leaves an equivalent edge. Others are harder and have sprinklings of little dots inter-spaced with plain patches – these are what is known as the ‘The Grecian Hone’ in old literature, despite it coming from Wales! The mythical Cutlers’ greenstone (not a single verified example exists – anywhere!) is supposed to come from the region where the Lynn Idwal seam runs close to a volcanic seam that metamorphosed the once slaty seam into various types of hone. It is mentioned in the MS of an ancient geologist as being forest green in colour with sparse sprinklings of lighter blue dots. It sounds comparable to some types of Grecian hone to me, but we have only the written word to guide us.

Moughton Whetstone

From the Yorkshire Dales, this is a rarely seen razor hone stone. These red and green rocks are from the Ordovician age and the peculiar and very attractive rings are an example of the Liesgang effect. The hones come from a very localised area, not found elsewhere, and were once in demand in Sheffield for use in the sharpening of razors, although these days examples are seldom seen. A 1985 field study by W. R. Mitchell mentions the stones use as a whetstone and cites two other sources from the 1700s and 1800s. Other sources specifically cite the fact that the Sheffield razor trade made use of these hones, but I have not been able to track down a definitive text. In use they are somewhat slow and the edge left is akin to that left by a hone in the region of 7k or thereabouts, depending on the specimen: some are finer than others. Hard to fit into a honing progression they are more for the collector in my opinion rather than for honing.

Japanese Nakayama

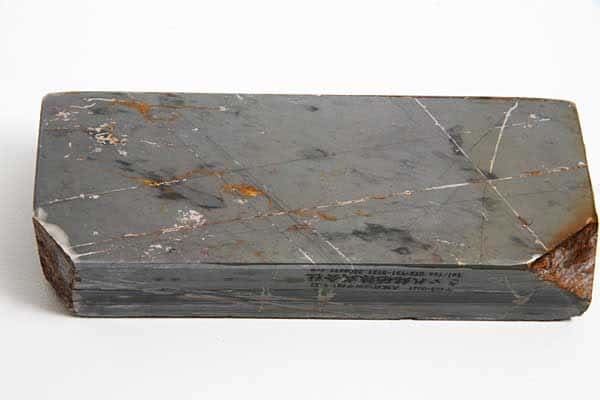

A fine vintage hone from Japan. The Nakayama is the only type I have used – it is a very hard finishing hone, and quite versatile. A slurry may be built-up using a natural “nagura” stone and in use, the slurry particle size breaks down finer and finer, so the razors edge becomes more refined as you continue to hone. That makes the hone quite versatile – one may go from a 4,000 or 8,000 grit hone straight to the Japanese hone, and progress as if going through intermediate stones. Giving a grit size is problematical with natural hones, and even more problematical here: every single stone has different qualities, but I would rate the one I used as anything from 12,000 to 16,000+. They require lapping only at extended intervals, being so hard. Often, the stone has lines and fracture marks in it – these appear to have been made long ago during the stones formation, and other material has seeped through the cracks and mineralised to form the solid stone. Each one has to be examined quite thoroughly for its ability to impart the best edge on a razor – some faults and inclusions bar them for use as razor hones.

Below is a small natural “nagura” or rubbing stone, used for raising a slurry and for localised corrections of the Japanese hone. It is a fairly soft stone, and is available in a number of grit sizes – this one is approx. 1000 grit. Unlike synthetic naguras, these break down quite quickly during honing, so the grit size becomes finer and finer:

That concludes my rather limited round-up of hones. Of course, there are many more honing stones such as Cutlers Green Hone from Snowdonia; Devonshire Oil Stone from Tavistock; Welsh Yellow Lake Hone; Silkstone hone from the UK and so on, as well as the vast variety of natural Japanese Hones – very exotic and potentially very expensive! As stated above, the views expressed are my own and formed after years of using these products – no doubt others have different or conflicting views.